Turbine handpiece VS contra-angle handpiece

The advantage of the turbine handpiece is its simple and strong structure, cheap price and lighter weight. However, the detrimental effect of the high frequency noise produced by turbines on the operator's hearing has become a very serious problem for many years. As opposed to turbine handpieces, electric motors run quieter and are less damaging to hearing. Considering the amount of tooth tissue removed per unit time, electric motors equipped with water cooling systems are more advanced than turbo motors in terms of grinding.

the

In recent years, with the continuous development of motors, it has become clear to manufacturers that the ergonomics of dental handpiece weight and size play a decisive role in the purchase decision. Instruments manufactured within the last three to five years have seen significant reductions in weight and size. A 30% reduction in weight and 15% reduction in size is not uncommon. This advancement stems from a reduction in the size of the ISO motor joint. Note that the "reduced contra-angle handpiece" can only be used on motors with a smaller size E-connector. Even with the general trend toward lighter weight, turbine handpieces are smaller and lighter than electric motor-driven contra-angle handpiece systems.

The head smaller, it is easier to reach the treatment site, and it has a better view of the treatment site. Buyers should consider not only the diameter and height of the machine head, but also the working height of the machine head (machine head + bur). The smallest turbine handpiece has a working height of approximately 17mm (bur length 16mm). These micro-turbine handpieces have a diameter of less than 9mm and a height of about 10mm. Despite their ultra-small size, they pack a punch of power. Products must be designed for special applications where only small head sizes can be tolerated. This means that the microturbine handpiece can be used with minimal invasiveness, and for patients with small openings (children and the elderly). Some manufacturers go so far as to integrate only two impellers into the turbine handpiece to meet these demands.

Turbine handpiece rotors tend to suck in ambient air as they decelerate. Therefore, there is a risk of polluting gases being sucked into the interior of the turbine handpiece. Modern turbine handpieces are equipped with so-called sanitary heads. This innovative system prevents external air from being sucked into the bypass line.

The idling speed of the turbine handpiece (about 400,000 rpm) is an indicator of cutting performance. The advantage of electric motors is that speed and torque can be controlled very easily. The speed of the brushless electric motor is controllable in the range of about 100 to 40,000 rpm. The motor's torque is very consistent throughout the rev range. More and more dentists are choosing to use electric motors. If the service life, sanitation, wear and sterilization are comprehensively considered, brushless electric motors are more popular than brushed electric motors.

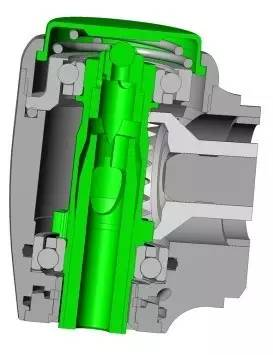

FG Collet System for High Speed Instruments, 1.6mm

The current standard is the push button type. This system can replace the bur without tools. The needle can be changed with minimal pressing force. But on the other hand, the triggering force of the pressing surface should not be too low, so as not to cause the risk of accidents, such as the chuck being triggered and released when it hits the patient's cheek. The holding force must be sufficient to clamp the bur securely. Swallowing or inhaling a bur can be life-threatening to the patient. The high speed of rotation of the handpiece generates strong centrifugal forces, for which the manufacturer must provide the best possible solution for simple replacement and secure clamping of the burs. The quick and easy operation and the strong holding chuck system are ideal for holding the bur securely in place.